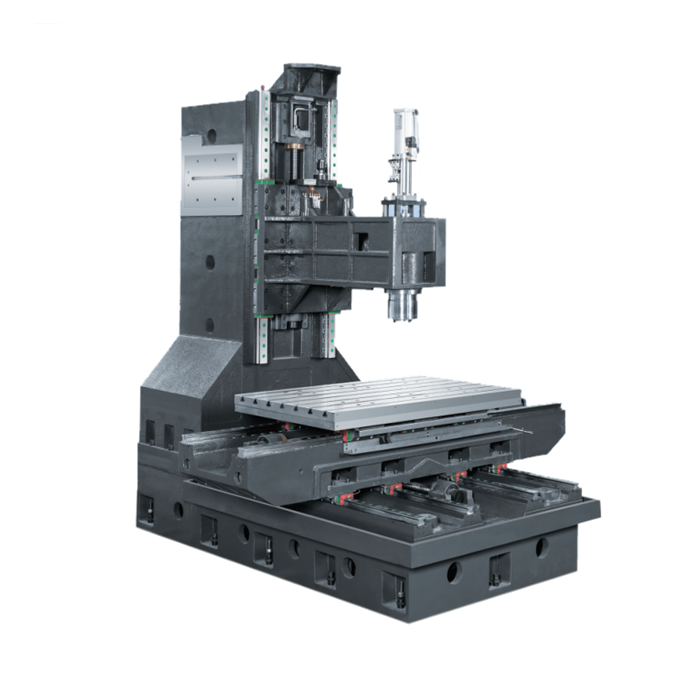

+The casting structure adopts reinforced design. The wall thickness of the casting is reasonable and the reinforced ribs are carefully configured to achieve extremely high rigidity and high precision.

+ Large-diameter precision ball screws are directly driven by servo motors and supported by special bearings for ball screws, so they can be effectively transmitted.

+Driving torque, capable of carrying heavy cutting loads. The ergonomic face plate design makes the operator easy and comfortable to control, and is used for efficient heavy cutting processing. Large-volume production of automotive parts, precision parts, and mold processing.

About the features of FV-1370

-The machine bed weighs 8 tons, has a high-rigidity and high-precision four-rail design, and the Y-axis adopts four heavy-duty 45mm roller guide rails, making the workbench as stable as a mountain during large-area processing displacements, and the tabletop is not easily deformed. The X-axis and Z-axis use 55mm ultra-wide guide rails with 6 oversized slide blocks, which greatly improves the processing rigidity and cuts iron like mud! All are made of high-quality resin sand wear-resistant castings, strong ribs, oversized columns, and honeycomb structure.

-The processing range is larger than that of ordinary models, and the rigidity of the machine tool is greatly enhanced, so that the machine tool can more effectively absorb the vibration during heavy cutting during processing, thus improving the accuracy and smoothness of the workpiece. Through finite element structural analysis, a large number of reinforcing ribs are used inside the casting to optimize the internal stress structure of the whole machine and ensure the rigidity and stability of the whole machine.